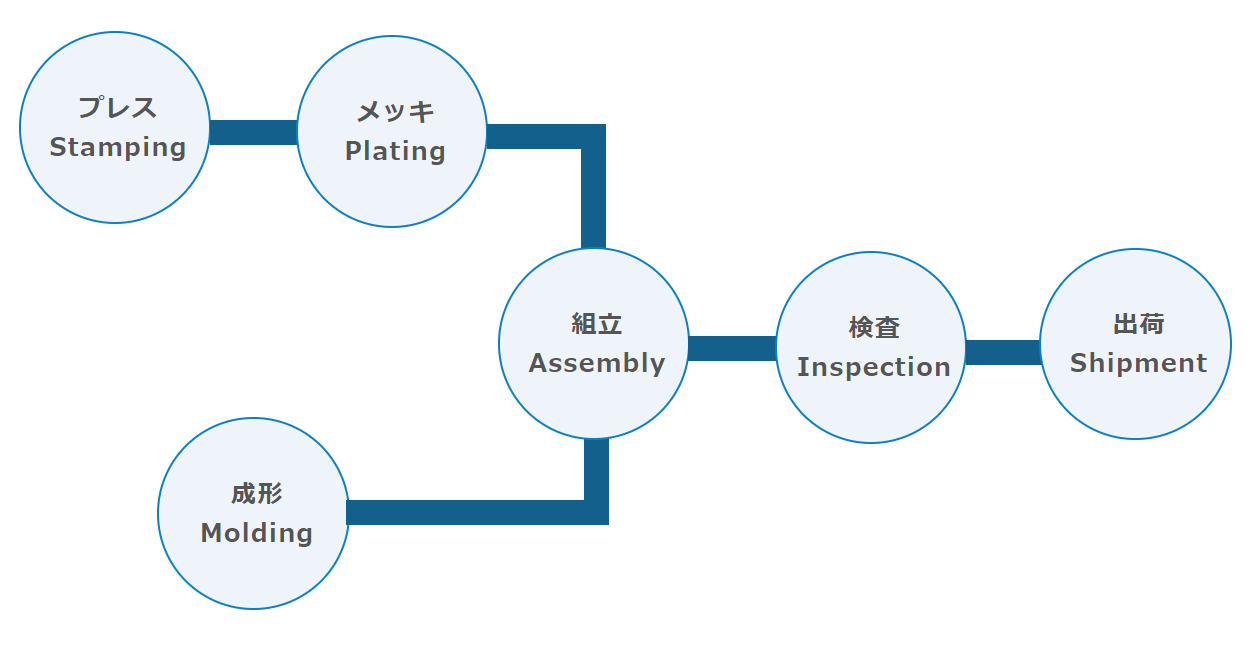

事業概要(生産体制)

一貫生産体制により安定した製品供給を実現しています。

部材から最終製品まで。

KELの一貫した生産体制は品質と納期でお客様のご要望にお応えします。

部材から最終製品までを一貫生産。

卓越した加工技術が、そのクオリティを生み出します。

当社が製品に対して、常に追求しているのは高付加価値です。最先端の技術を駆使して開発した製品には、その技術開発力に適合した生産ラインが必要だと考えます。プレスやメッキ、成形加工など、部材の一次加工から組立、品質検査まで、一貫した生産体制を整備し、製造面でも、そこに関わるすべての技術要素を保有し、進化させています。先端を行くエレクトロニクス機器の開発は、モノづくり日本にとって重要なテーマです。当社は、エレクトロニクス機器の進化に不可欠なコネクタ製品を日本国内で高品位な一貫生産によってお届けしています。その卓越した品質をぜひご実感ください。

柔軟な生産体制によって納期に対応。スピードとタイミングを逃しません。

部材から製品までの一貫生産のメリットは、品質に限ったものではありません。生産計画においても柔軟性が発揮でき、お客様が望む納期に対応できる体制を整えています。先端の生産ラインと経験に裏付けられた生産技術で、お客様のニーズに対応しています。また、既存製品の仕様変更にも柔軟にお応えします。当社の生産体制には、お客様の満足を約束する確かな品質があります。

多様化するコネクタとその関連部品。

KELの柔軟な生産システムが、あらゆるニーズに対応しています。

生産拠点は山梨に 2 ヶ所、長野 1 ヶ所の計 3 拠点を構えています。

また大量ロット品などの一部製品は海外の委託加工会社にて生産しています。

山梨事業所

建物面積(延べ床面積):5,179.53 ㎡

南アルプス事業所より生産機能を移転し2013年に操業開始しました。フローティングコネクタを中心に、高度な技術を要する少量多品種生産品のコネクタ・ラックの供給、新製品の立ち上げから量産化まで柔軟に対応しています。またクリーンエリアの設置や人とモノの動線分離など生産環境を整備し、生産性・品質の向上を追求しています。

長野事業所

建物面積(延べ床面積):3,026.28 ㎡

ケル独自の設計による全自動組立ラインを完備しており、ケルの看板製品であるハーフピッチコネクタを筆頭に、大量生産品に十分対応できる生産拠点です。またハーネス加工品の供給もしています。

南アルプス事業所

建物面積(延べ床面積):4,949.04 ㎡

山梨事業所に生産機能を移転後、部品加工専門の工場として稼働しています。コンタクト・メッキ・インシュレータ(プラスチック成型部品)の部品加工ラインを有し、部材から組立までの一貫生産体制を確立しています。