ケルの強み K-ELements(ケイ・エレメンツ)

KEL を支える要素(Elements)=K-Elements を紹介します

高性能・高品質な製品を追及するR&D活動

オリジナリティがある製品づくりを目指す研究開発

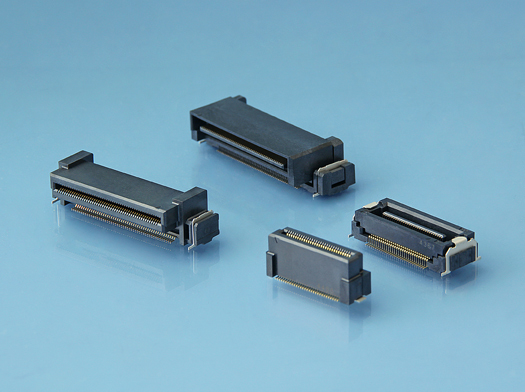

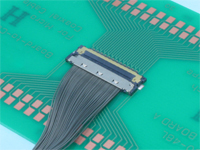

日々進化を続けるエレクトロニクス機器にあわせて、コネクタにも高性能化が求められています。ケルは先進の研究開発により最先端技術の創出に取り組むとともに、積極的な技術提案を通じてお客様の期待に応える品質・サービスの提供に努めています。付加価値の創造を通じて顧客満足度の最大化を図ること、それがケルの使命です。

ケルの開発方針と製品の特徴

"創意をもって、差別化できる製品づくりを目指す"

- 製品にオリジナリティがある

- 製品の品質、信頼性が高い

- 最先端技術を投入している製品である

- 安全で安心して使える製品である

- 業界での製品知名度が高い

- 使い勝手を最大限考慮した製品である

- 環境に適応した製品であること

研究開発施設

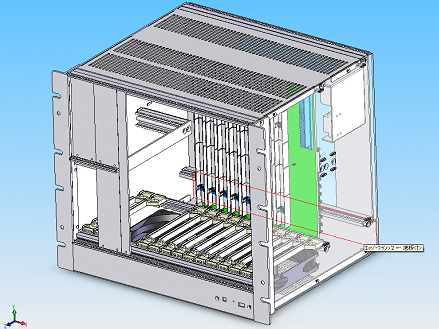

ケルでは本社内に研究開発部門を置いています。豊富なノウハウを蓄積した技術部門がいることで、営業部門から集約したお客様からのニーズを即座に伝達できる体制を整えています。また最先端の設備を擁する生産拠点との連携により、タイムリーな新製品・新技術の創出が可能になっています。また継続的な研究開発こそ将来の収益の源泉と位置づけ、積極的に研究開発投資を行っています。

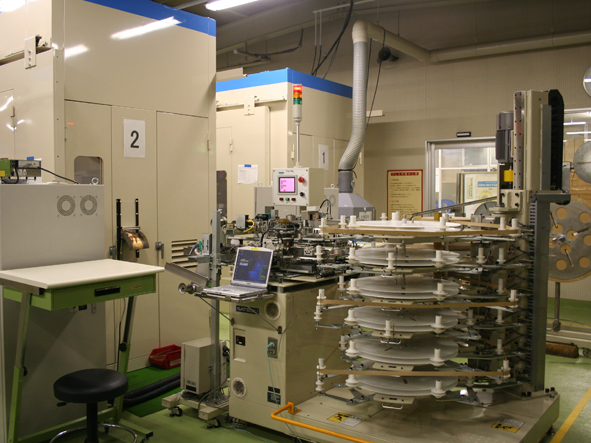

安定生産体制の確立

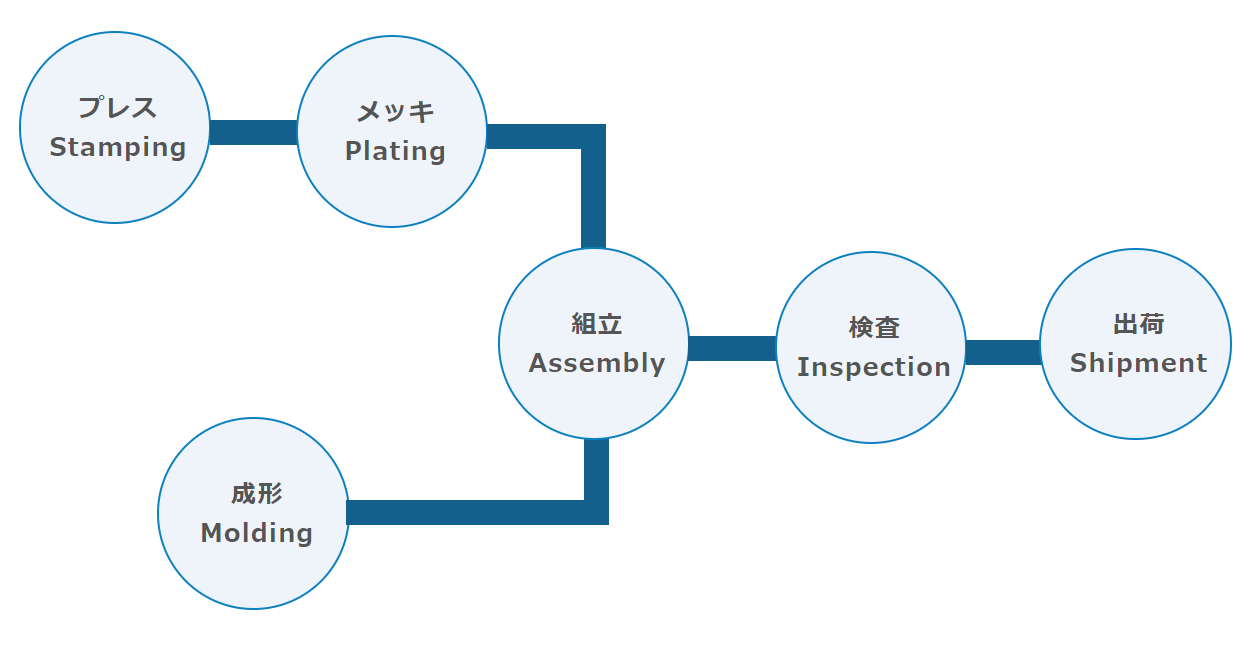

一貫生産体制の確立・・・部材調達から組立まで

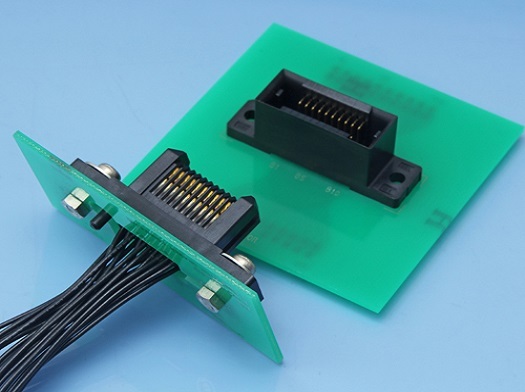

ケルではプレス、メッキ、モールド成形といった部材の一次加工から、組立、品質検査に至るまでの全工程を自社内で完結できる信頼の一貫生産体制を確立しています。また一貫生産体制を確立することで、研究開発の機動力と顧客対応力を発揮することができます。汎用性の高い自動組立ラインは、お客様の求める仕様・機能に柔軟に対応するだけでなく、特注品を含む多品種少量生産を可能にしています。

プレスライン

メッキライン

ケルの一貫生産体制

プレス Stamping

最先端のマシンにより、リールに巻かれた平板の金属材を高精度、高性能のコンタクトに加工しています。

メッキ Plating

プレス加工されたコンタクトを鉛フリーメッキに対応したラインで、表面処理加工(金メッキや錫メッキ)しています。

成形 Molding

画像検査機能付き射出成形機やインサート成形機などの高性能な設備で、インシュレーター(プラスチック成形部品)を加工しています。

組立 Assembly

工夫を凝らしたラインレイアウトと万全の生産管理体制の下、抜群のスピードで高品質な製品を生産しています。

検査 Inspection

完成した製品に電気的試験、出荷検査を行った後に梱包・出荷となり、お客様のお手元に届きます。

プレス

Stamping

メッキ

Plating

成形

Molding

組立

Assembly

検査

Inspection

出荷

Shipment